EDGETEQS-370

EDGETEQ S-370.

The next generation of

Edge banding machines.

Based on our 20 years production history in Shanghai we are continuously working in serving you with high-end technology solutions. The EDGETEQ S-370 is the result of German Technology and Asian requirements and yet at an affordeable investment.

CONTENT

Presentation EDGETEQ S-370

Unit modules

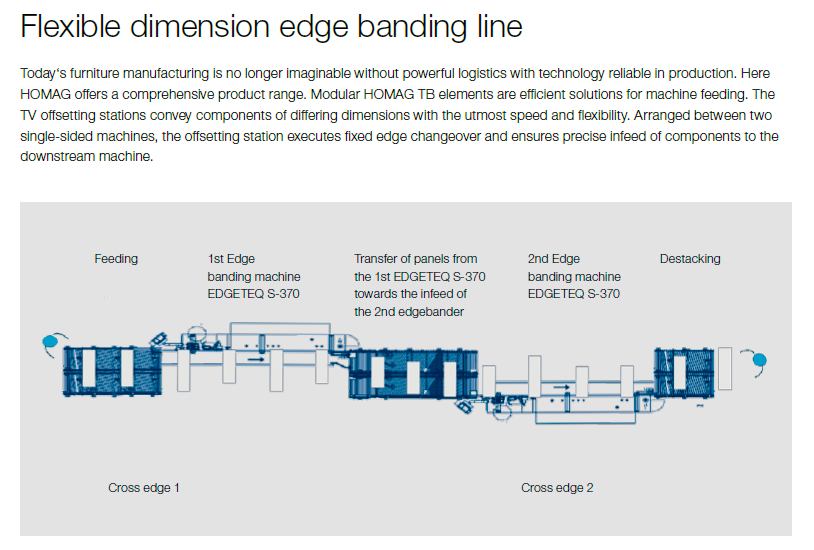

Flexible Dimension Edge Banding Line powerTouch

Technical Data

Life Cycle Services

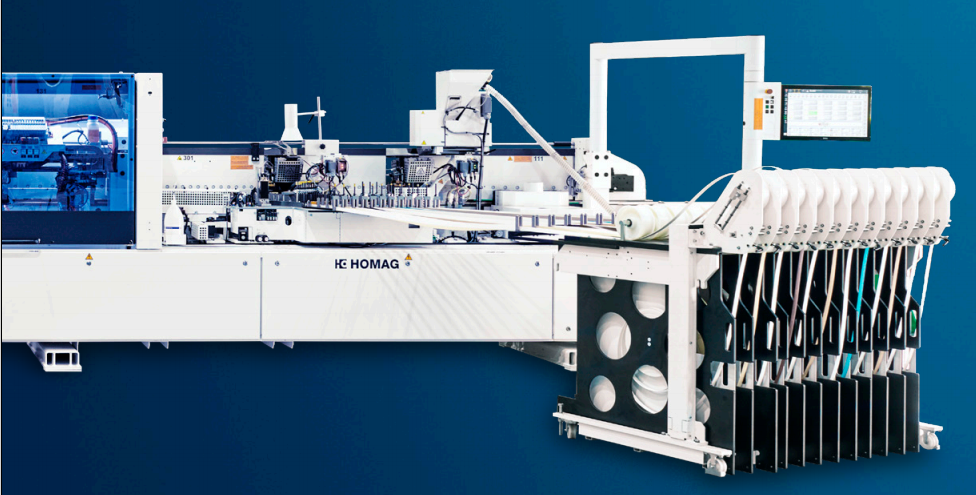

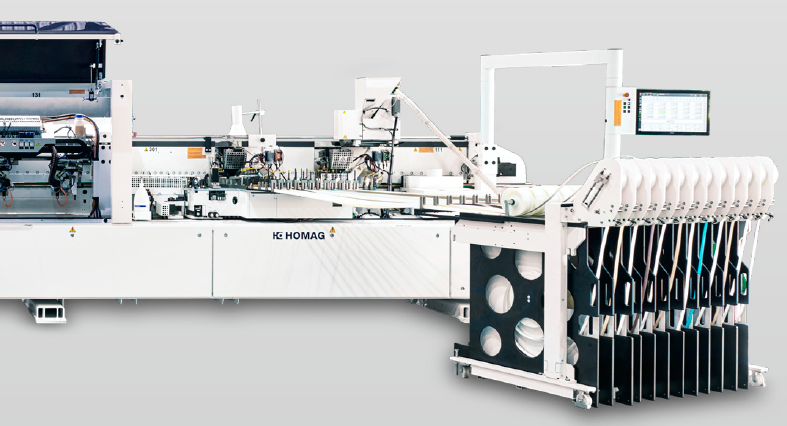

EDGETEQ S-370

the next generation of Edge banding machines

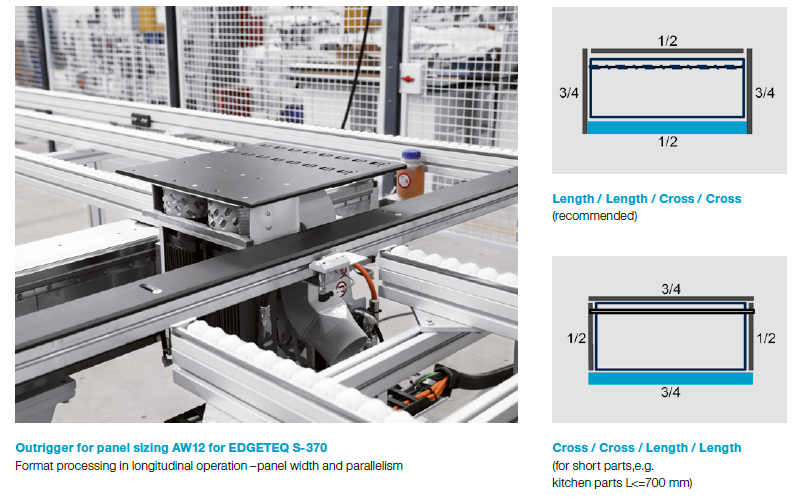

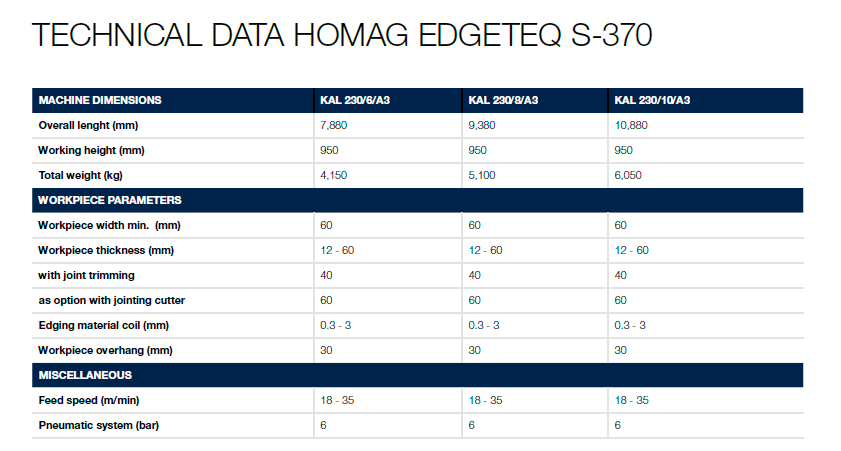

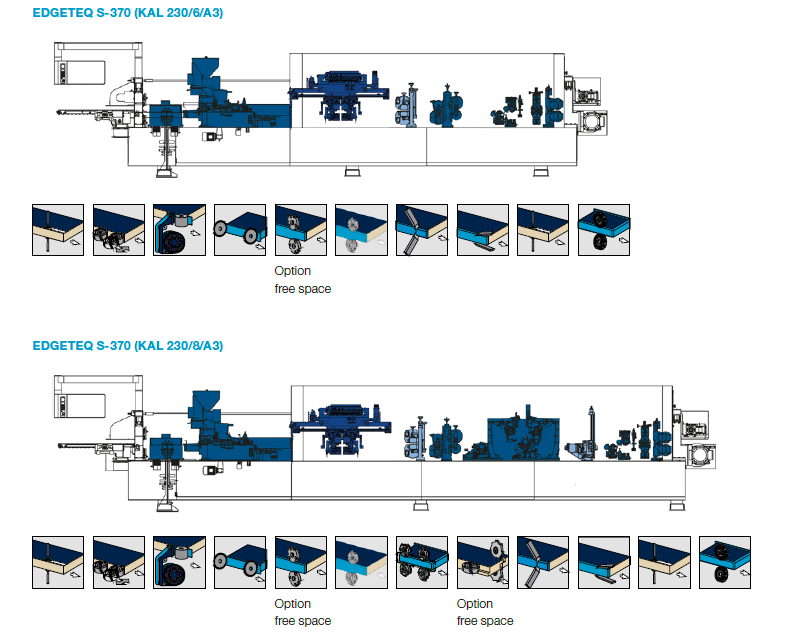

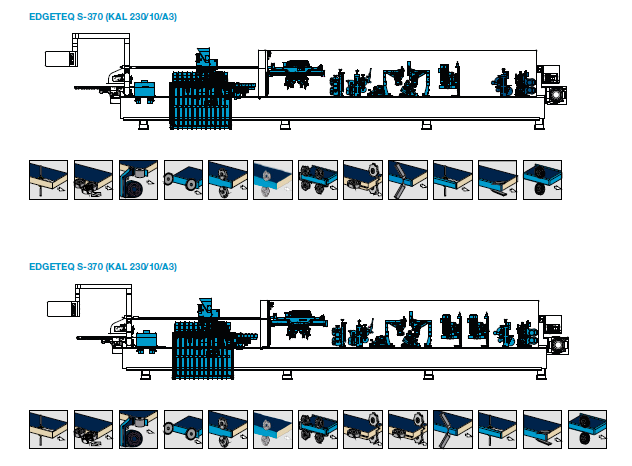

In case of the EDGETEQ S-370 you can select between 3 machine lengths according to your requirements. The EDGETEQ S-370 you can get without profile trimming unit, with profile trimming unit and different options.

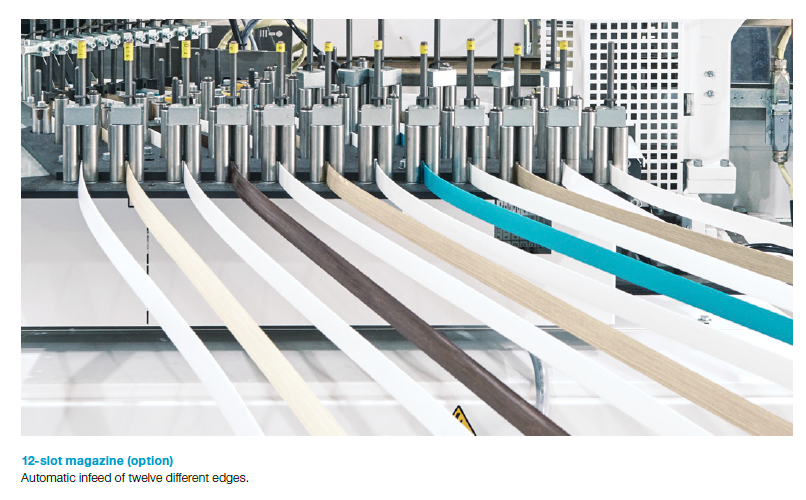

EDGETEQ S-370 with 12-slot magazine

EDGETEQ S-370 series –

the most important features of the models

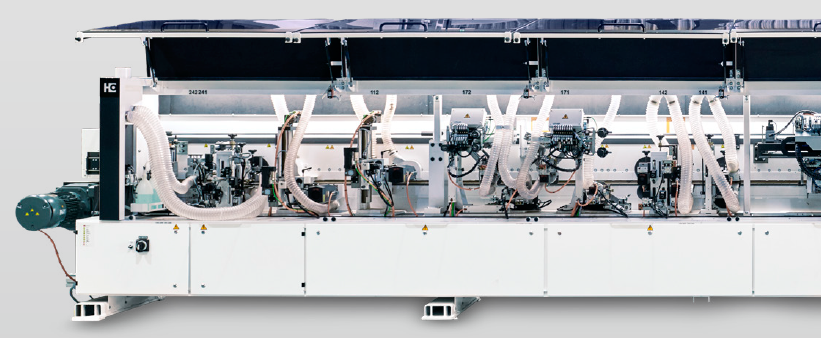

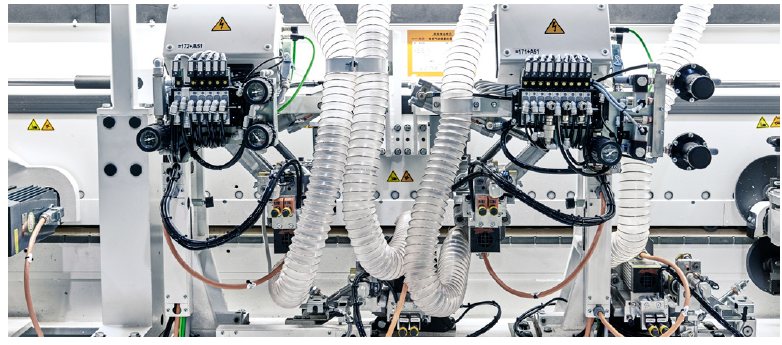

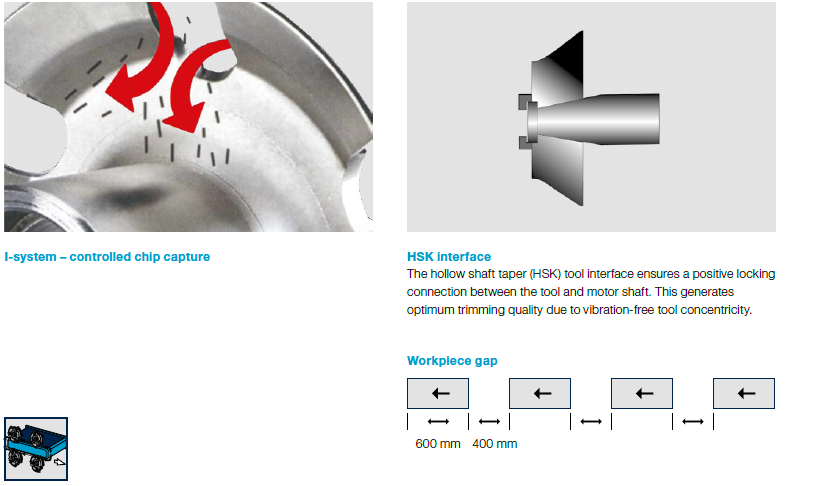

The EDGETEQ S-370 series is characterized by its comprehensive equipment standard: Stable basic machine with sliding chain

for high processing quality, top pressure in steel for precision workpiece guidance, all trimming tools complete with I-system for

optimum chip disposal and processing quality. Variable feed rates in two performance categories for high productivity.

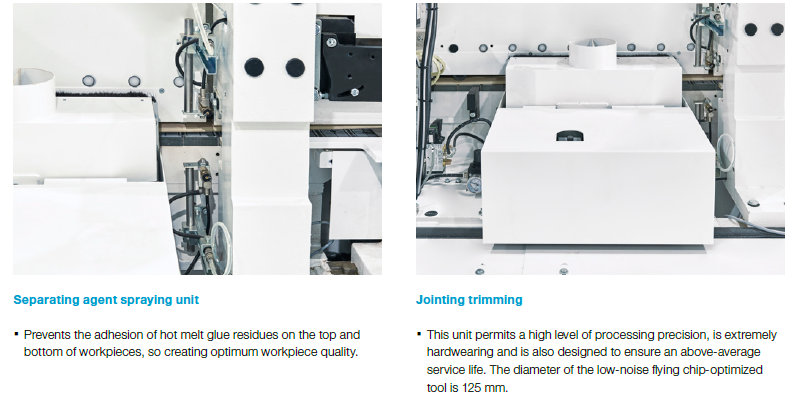

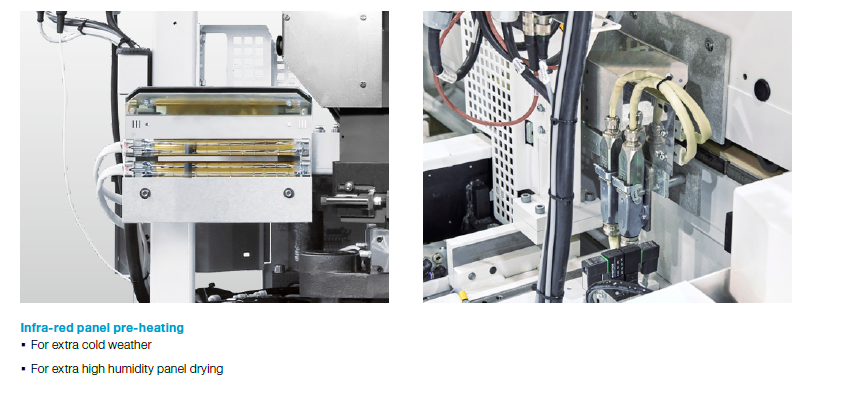

Pre-gluing processing

The separating agent spraying unit and the jointing trimming unit ensure optimum preparation of your workpieces for gluing. The

sprayed separating agent application simplifies the removal of glue residues. The jointing trimming unit provides the perfect basis

for splinter-free glue joints with a consistently high standard of product quality.

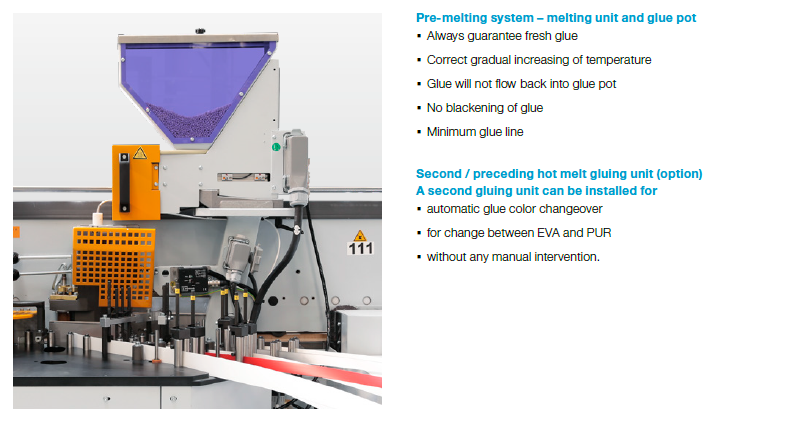

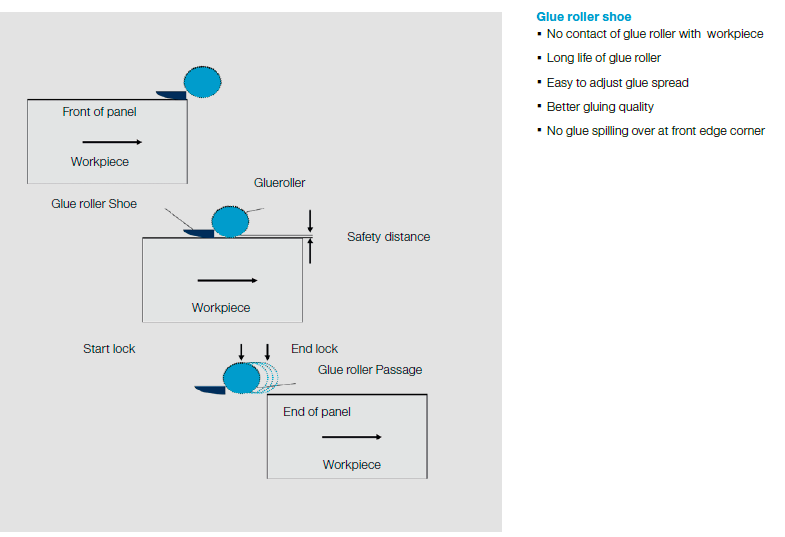

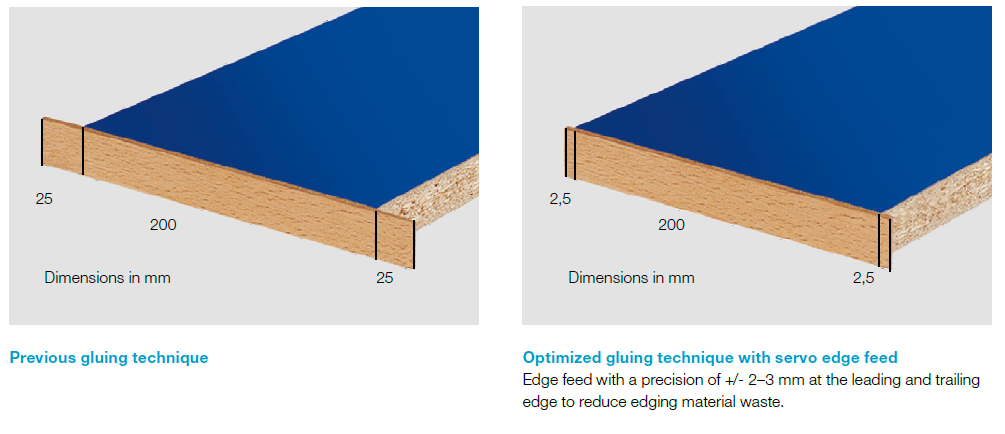

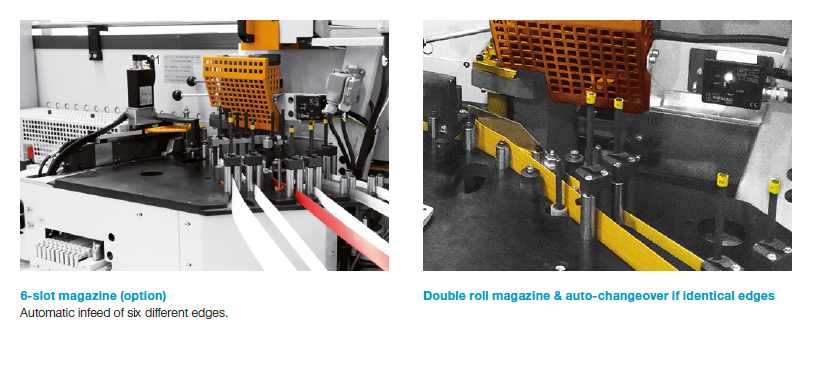

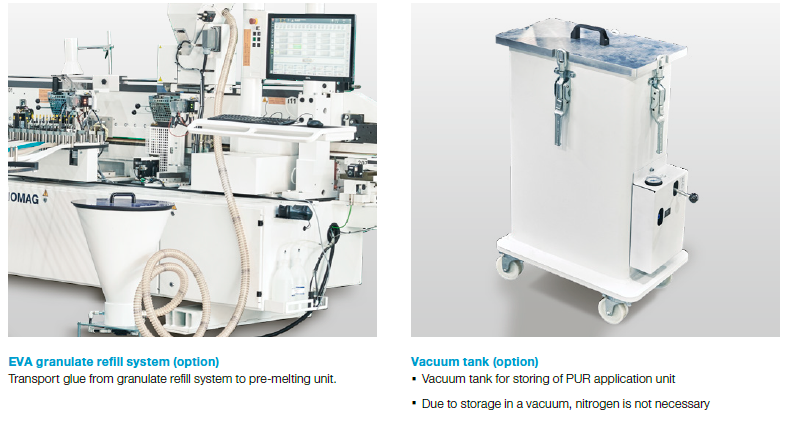

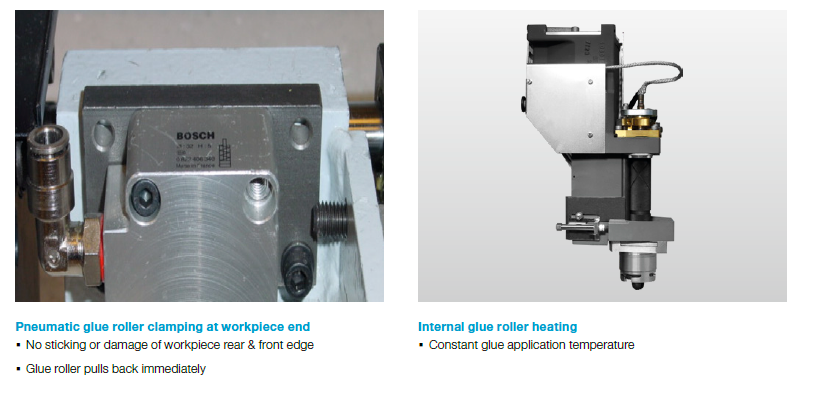

Best result with HOMAG gluing unit

HOMAG gluing units are ideal for a fast, positive-locking glue bond. An EVA pre-melting unit comes as standard. The heated

glue roller ensures an optimum gluing temperature. The magazine height adjustment permits different edge heights to be

processed with a consistent workpiece thickness. On request, the gluing unit can also be individually equipped with a PUR

pre-melting unit – allowing rapid changeover between two different colors or PUR.

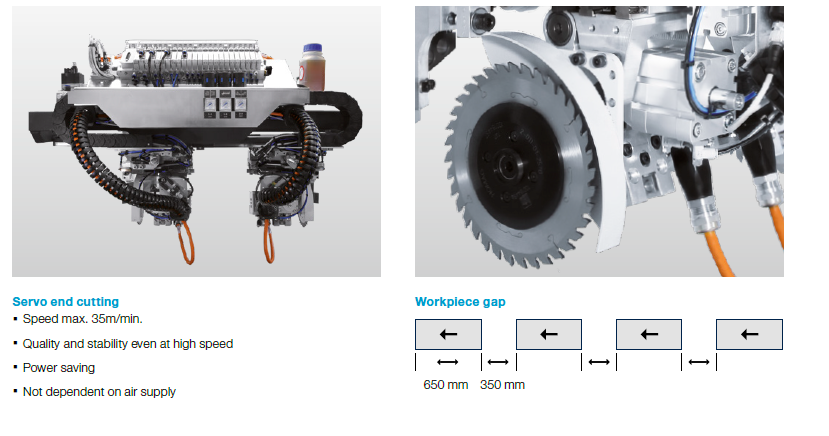

High speed servo end cutting –

35 m/min –high speed profit

The servo end cutting unit prepares the workpieces perfectly for subsequent trimming operation. The face side can be snipped

either straight or with chamfer. The servo-controlled front and rear cutting device is extremely stable, free from compressed air

and other external factors. The unit is convenient for sensitive materials, too. So a high standard of processing quality is ensured.

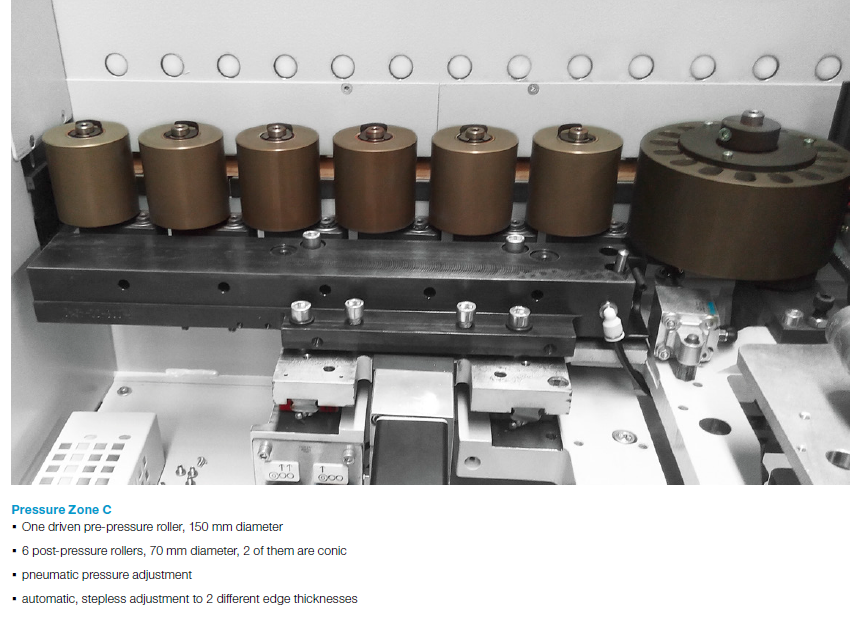

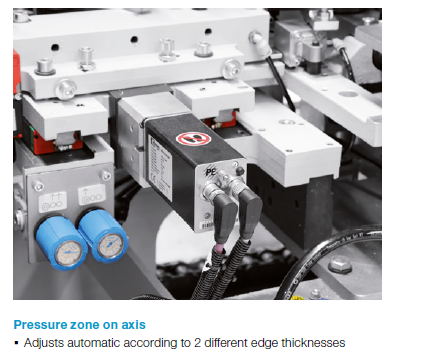

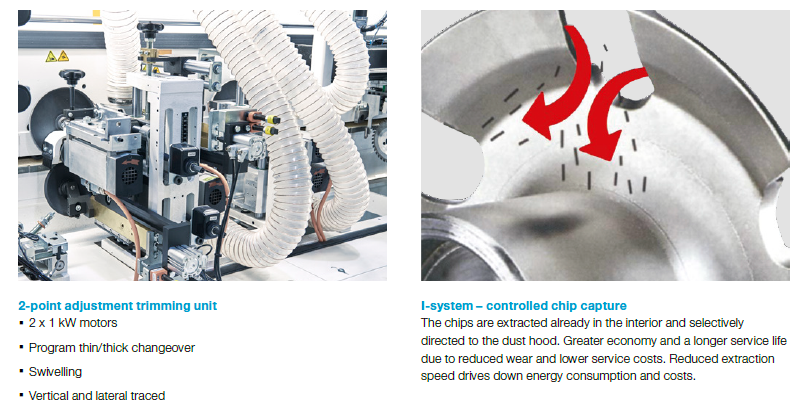

Program reset thin / thick edges

With the rough trimming unit and the 2-point adjustment trimming unit – chamfer/radius trimming unit – HOMAG offers the right

solution for the processing of projecting edges. The 2-point adjustment Trimming unit is ideal for rapid changes between thin

and thick edges because of its electro pneumatic 2-point adjustment. The rough trimming unit is suitable for rough trimming the

upper and lower edge overhang.

High speed corner rounding –25 m/min – high speed profit

The profile trimming unit FF32 is a proven technology for chamfering and rounding-off edges on workpiece front and rear edge

with combined tool. By dividing the cut over four motors, each corner can be processed in synchronous rotation. This lends

corners a perfect trimmed finish.

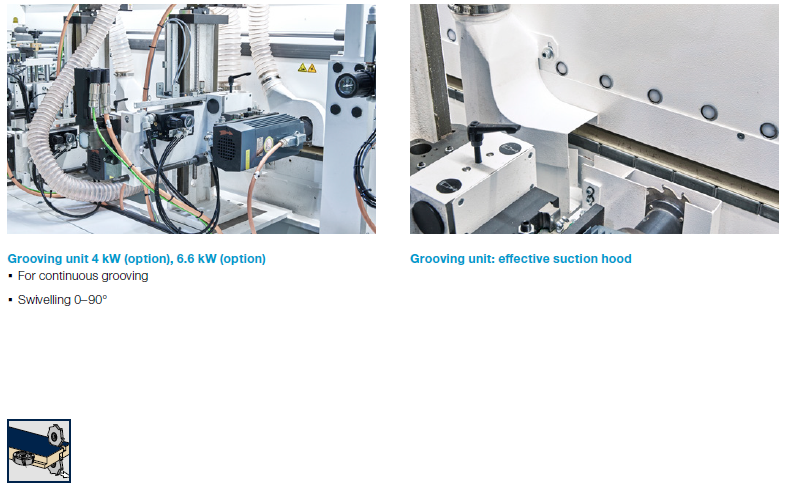

Flexible grooving solutions

The grooving unit – for grooving, rebate trimming and profiling – can operate from two directions: vertical from bottom and

horizontal into the workpiece edge.

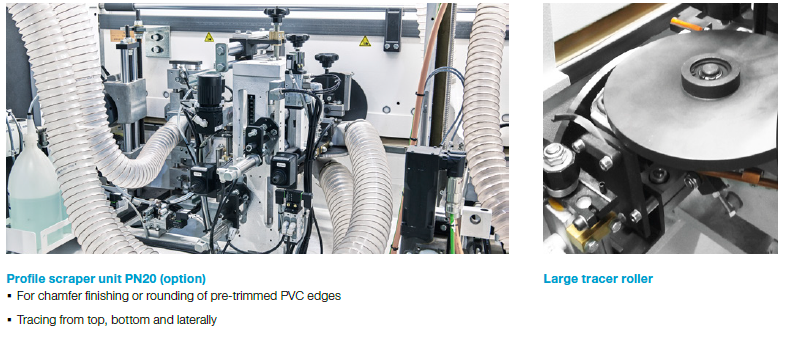

Profile scrapers

The quality of your products is increased by the use of profile scraper units. They

smooth trimmed edges to achieve an optimum appearance.

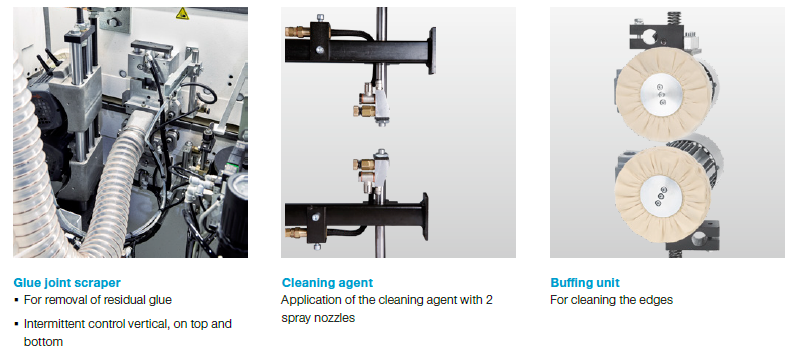

Finishing units

With an ideally coordinated finishing unit, HOMAG adds a perfect, high-quality final touch to your products. The unit for finishing

the longitudinal edge, consists of a glue joint scraper, the application of a cleaning agent and a buffing unit.

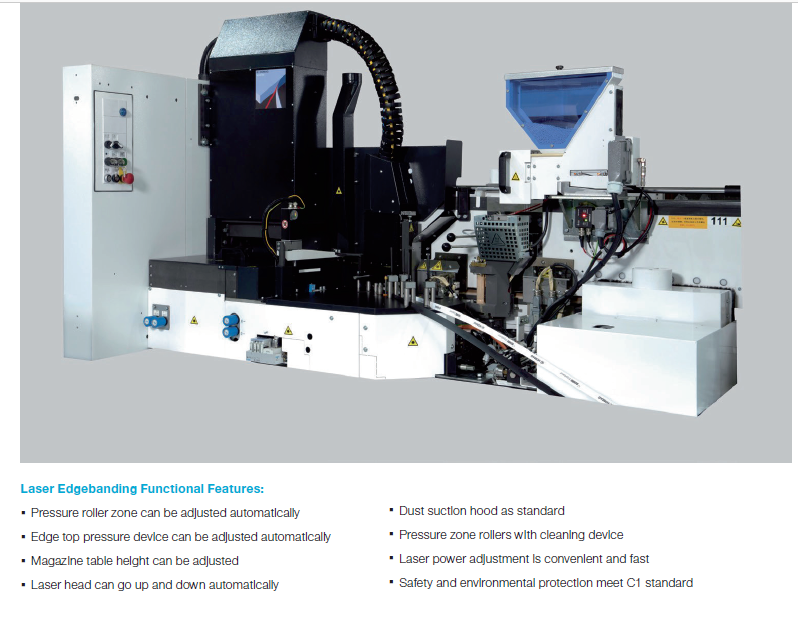

EDGETEQ S-370 / laserTec

This edgebanding machine combines the advantages of 7 years of research and development experience, and is a reliable, highquality

product.

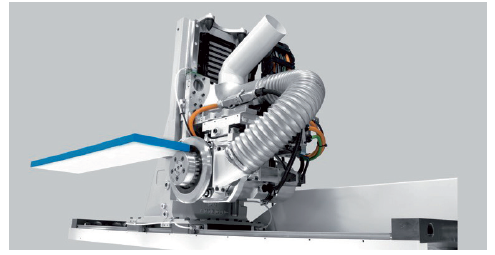

laserTec is the EDGETEC S-370 high-speed laser edgebanding technology.

HOMAG CHINA recently launched the new generation EDGETEQ S-370 (KAL230) / laserTec, which uses this advanced laser

engraving technology. It is suitable for 12-40mm thick workpieces and can achieve higher processing precision and efficiency.

This technology is widely used in the furniture, decorative and other industries, and its performance has been widely recognized

by users.

It is an efficient, reliable and safe industrial laser edgebanding solution.

Note: The product is made of high-quality steel structure, and the design and manufacturing are in full compliance with German engineering standards.

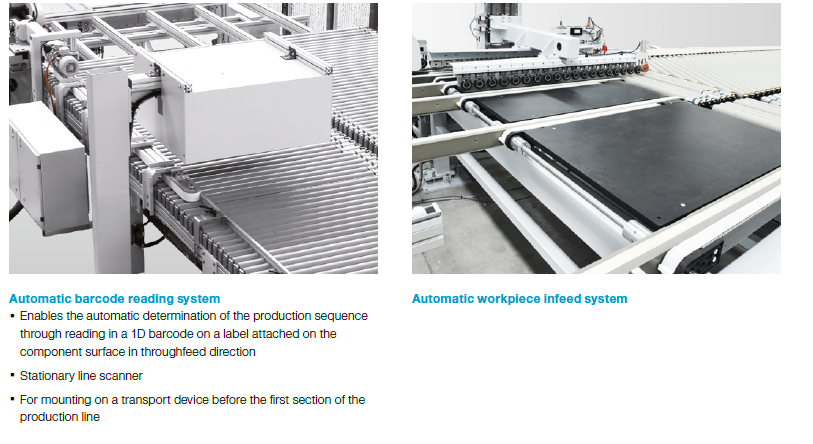

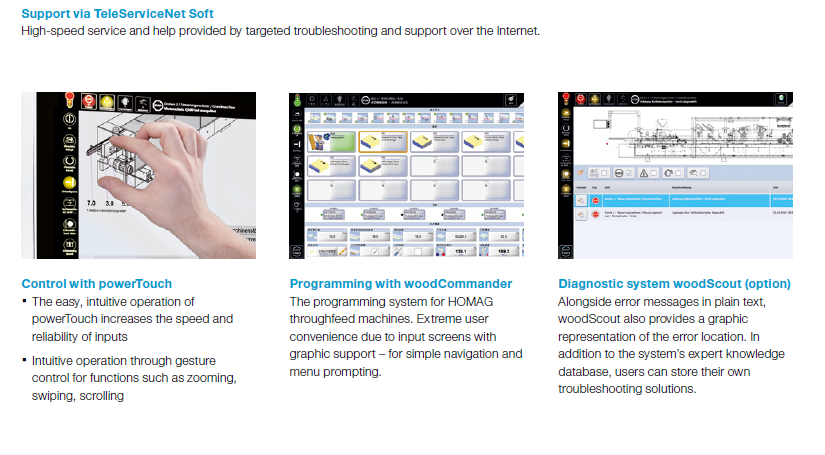

Control with woodLine software package

With the modular software package woodline you can control two processing machines of the series EDGETEQ S-370 as well

as feeding and transfer from the first machine to the second one. Functions like Section-wise reset, Barcode reading system,

Flexible edge sequence control or Resetting in the gap are included.

There are many parameters that must be defined to tell the machine and the aggregates what to do. Without a barcode control

each of these parameters must be defined at the machine.

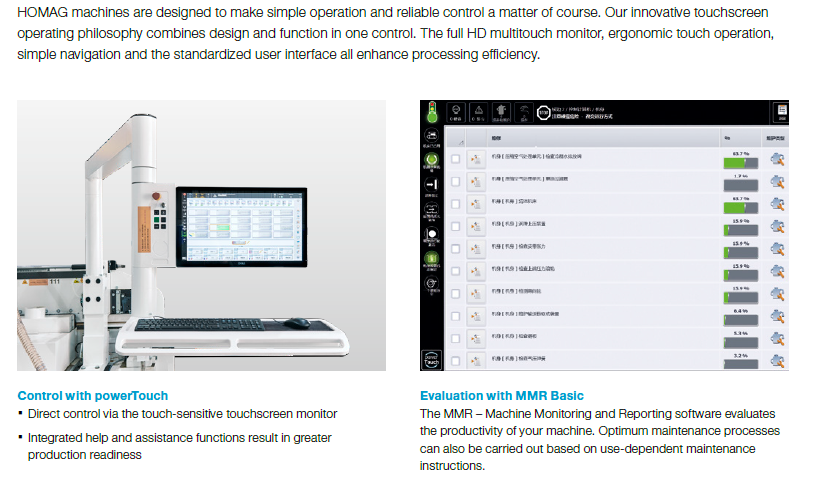

powerTouch – the innovative control system:

easy, equal, ergonomic and evolutionary

Contact Us:Mr. Zhan,TELL:18601257090

Address: No. 502, Guantai Road, Houjie Town, Dongguan City, Guangdong Province

Company Name: Dongguan Renke Woodworking Machinery Co., Ltd.